SORALUCE to support the evolution of the energy sector in partnership with the Nuclear AMRC

A long term agreement brings SORALUCE into partnership with the Nuclear Advanced Manufacturing Research Center (Nuclear AMRC) to push forward the development of manufacturing processes for civil nuclear and other innovative energy sectors.

The Nuclear AMRC was established in 2009 to combine the knowledge, practices and expertise of manufacturing companies with the capability of universities. It is led by the University of Sheffieldwith support from The University of Manchester Dalton Nuclear Institute. Over 40 companies have joined the Nuclear AMRC as members, from reactor providers and top-tier suppliers to providers of specialist equipment and services.

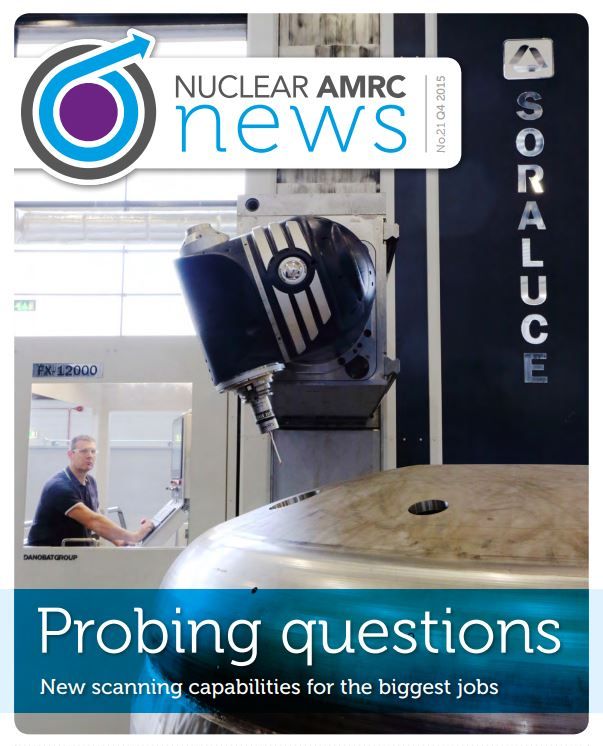

The Nuclear AMRC´s 8000m2 research factory opened in the year 2012, and is now home to over £28 million worth of state-of-the-art manufacturing equipment – including a SORALUCE FX 12000machine, the world’s largest machining center of its kind available for collaborative research. This machine is used for the joint research and improvement of key manufacturing processes for complex parts that may have not been improved in the past 50 years due to the limitations on the manufacturing standards of a very conservative sector.

By taking membership of the Nuclear AMRC, SORALUCE will focus on bringing new solutions to the energy sector, including processes and technologies that it already provides to other customer sectors.

Nuclear AMRC Operations Director Stuart Dawson says: “The machine will be put to work on a variety of pressure vessel and reactor internal parts, mostly of steel/austenitic steel and often clad with nickel alloy, where a key issue is the maintenance of surface integrity. Such components regularly have an in-service life of up to 60 years in high pressure, high temperature and irradiated environments.

“A key part of the Nuclear AMRC’s work with the SORALUCE will be to fully understand the limits of machining and productivity, without adversely affecting the surface integrity of these work pieces.”

The advanced manufacturing research will provide more modern and flexible solutions that will help the energy sector to meet its challenges. SORALUCE will put together its knowledge in turnkey manufacturing solutions to expand the Nuclear AMRC’s capabilities and will make available some of the latest technologies in the market – such as the DAS System (Dynamics Active Stabilizer), a patent-pending system developed by SORALUCE that actively changes the dynamics of the machine and can break the rules of traditional manufacturing.

Jay Shaw, Head of Machining at the Nuclear AMRC, says: “We’re delighted to welcome SORALUCE to the Nuclear AMRC. Our SORALUCE FX 12000 centre has already proved its value to our industrial partners. Its size and capabilities allow us to undertake the most demanding machining tasks for a range of high-precision, mission-critical applications for the energy sector.”

“This is a very important partnership for our company as it is the perfect base for testing in the Energy field some solutions that are already standards in other sectors, and will allow us to work with customers to jointly develop new manufacturing concepts and solutions for a complex sector with very demanding needs,” says Xabier Mendizabal, R&D Director at SORALUCE.

T W Ward CNC Machinery LTD, the exclusive distributor for SORALUCE in the UK, has also taken membership of the Nuclear AMRC, providing the partnership with added value services and a maintenance contract.

This partnership is the base of the commitment of both SORALUCE and Ward CNC to contribute to the development of UK engineering capabilities, and has been already translated into successful deliveries to companies such as Babcock Intl, GE Oil & Gas and JCB Compact in the last year.