Danobatgroup has reached an agreement with Accenture to boost digital transformation

-

The group partners with the multinational professional services company to undertake the global digitalisation of the organisation.

-

This agreement aims to strengthen Danobatgroup´s position as a benchmark in innovation and consolidate its leadership in the supply of intelligent products and services for industrial manufacturing.

-

The Accenture consultants participated in the conceptualisation and the global strategic component, in addition to providing teams specialised in implementation.

-

The group will allocate an investment of more than 2 million euros over a period spanning the start of this project until the closure of its current strategic plan.

The industrial group Danobatgroup has reached an agreement with the multinational professional services company Accenture to boost its digital transformation, an integral process with which the machine tool manufacturer seeks to reinforce its position at the forefront of innovation and maintain its leadership in the supply of high value-added products and services, but also to optimise the management of its resources and continue to make progress in the construction of its model of governance based on excellence.

The agreement between the two entities dates back to late 2018, and has enabled the Basque group to undertake a holistic process that encompasses the development of new business lines based on intelligent products and services and the digitalisation of its entire organisational model, from order entry to dispatch.

This project also includes the strategic management of talent and financial resources, the creation of a value office with the capacity to track and monitor progress, and the construction of a new digital architecture to meet the challenges of the industry of the future.

"The project undertaken with Accenture is the result of an internal reflection in which we apprehended that digitalisation is much more than using advanced technologies in products and services. It is a new paradigm that changes the way we work and generates a new business culture, in which decision-making processes are more efficient. We are facing a global transformation and an opportunity that impacts every link in the value chain," says Danobatgroup´s Director of Innovation, Nerea Aranguren.

The group will make a total investment of more than 2 million euros in this transformation process from the start of the project to the end of this strategic cycle in 2020. More investment in this field is expected in the next strategic plan.

An agreement with results

The agreement has borne its first fruits: a roadmap for the generation of new intelligent products and services and for developing the scope of operational excellence has already been drawn up, and besides a beginning has been made with an information systems map for the new digital architecture.

"For this year we have programmed a total of 17 pilot cases of new developments, products, services or solutions with clients of our main brands Danobat and Soraluce, which are being developed following the new work methodology based on this process. The digital transformation allows us to break with systems based on linearity and enables us to perform proof of concept prior to industrialisation", says Aranguren.

The Elgoibar-based group has chosen Accenture because it is a company with a consolidated track record in the field of digitalisation applied to the industrial sector. In addition, last April the multinational inaugurated a new space of more than 2,000 square meters in the Zamudio Technology Park in Bilbao, aimed at promoting the digital conversion of industrial companies and cybersecurity.

New Industry X.0 Centre of Accenture in Bilbao

New Industry X.0 Centre of Accenture in Bilbao

"Acenture has been a key player in the conceptualization of the entire process, but in addition to providing the global strategic component, teams specialised in each of the branches that we are implementing were made available to us to ensure the success of the project," she adds.

A roadmap full of advantages

The digital transformation process will have a positive impact on the group´s operating account due to an increase in revenues from the development of new products and services, but also to a reduction in costs thanks to a more efficient operational and organisational structure. But not less important, it strengthens the position of Danobatgroup as a benchmark entity in innovation.

"Innovation runs in the DNA of the group, so we cannot fold our arms and let this new industrial revolution pass us by. Our company is a driving force in the technological and economic development of our area of influence, and as such we are and committed to taking the first step to open the way in our environment," adds Aranguren.

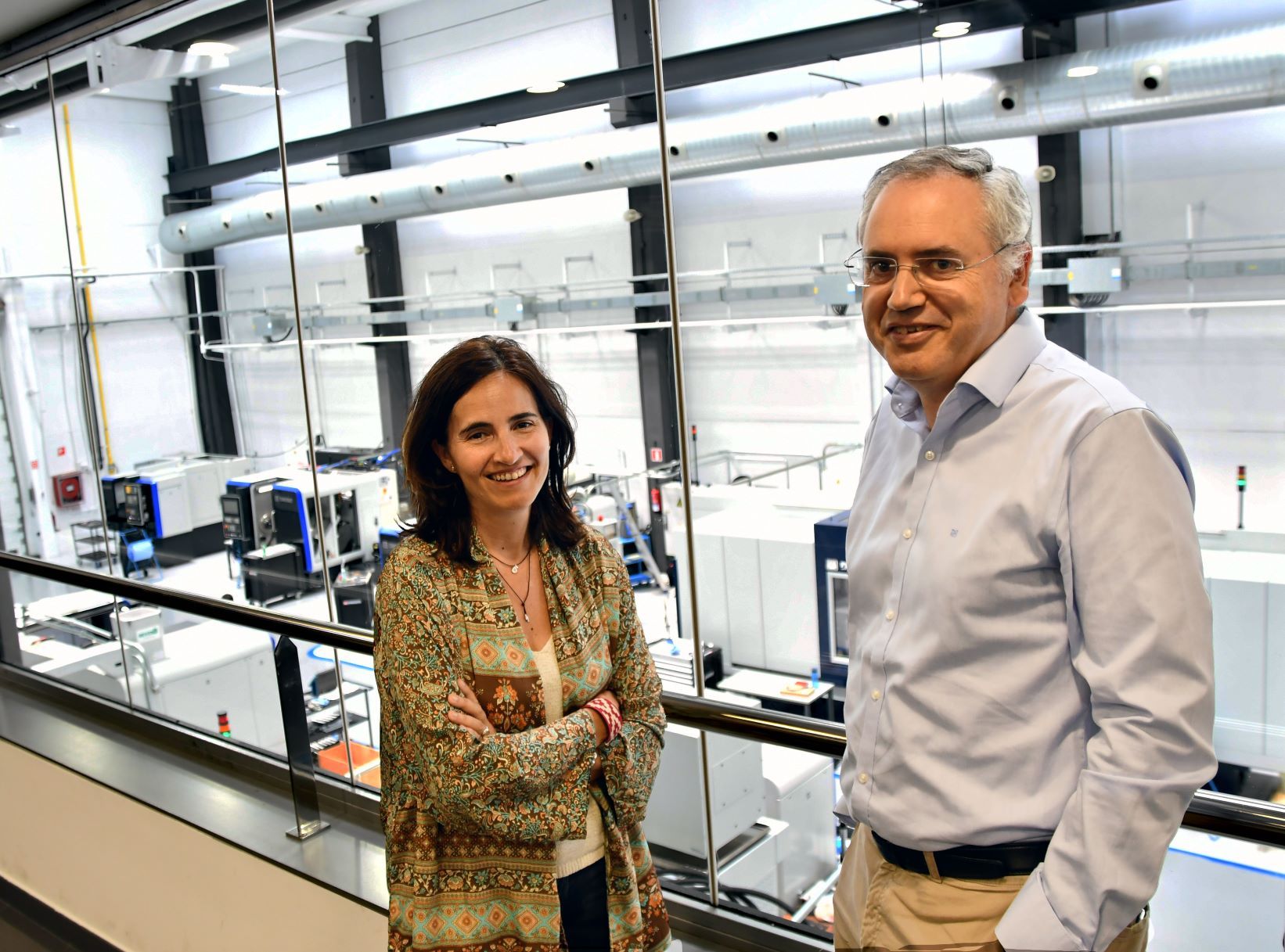

Nerea Aranguren Innovation Manager of Danobatgroup and Javier Mongelos IT Manager of Danobatgroup at the DGIH -Digital Grinding Innovation Hub- in Elgoibar

Nerea Aranguren Innovation Manager of Danobatgroup and Javier Mongelos IT Manager of Danobatgroup at the DGIH -Digital Grinding Innovation Hub- in Elgoibar

In particular, this process will have advantages for Danobatgroup´s customers, who will be able to count on state-of-the-art, more intelligent, interconnected and autonomous machines in their production plants.

"We´re going to help drive digitalisation in factories. Our customers can see us as a partner ready to take on the challenges of the future and capable of anticipating the needs of industry. With this process we seek to make the definitive leap to digitalisation, but without ever losing sight of our deep knowledge of the operational reality of industrial manufacturing," concludes Aranguren.

About Danobatgroup

With 65 years of experience in the field of technologies applied to industrial manufacturing, Danobatgroup has a staff of over 1,300 highly qualified people. The group is an international benchmark in the sector of machine tools and technologies applied to industrial manufacturing.