GOIMEK acquires the Zeiss Prismo Navigator machine for high precision measurements.

GOIMEK, a cooperative and part of the DANOBATGROUPspecialising in precision machining and machining of large parts, is extending its range of services aimed at demanding high-value and highly complex projects by adding a new Zeiss high precision measuring machine at its Mallabia facilities. This new acquisition is a response to the increasing market demand, which will enable the company to provide reliable services that cater for the needs of customers in the manufacturing industry area.

GOIMEK, thanks to its measuring systems, high-value technical resources and production means that ensure high quality and high precision, is positioned as one of the benchmarks for precision machining and large part machining in its field.

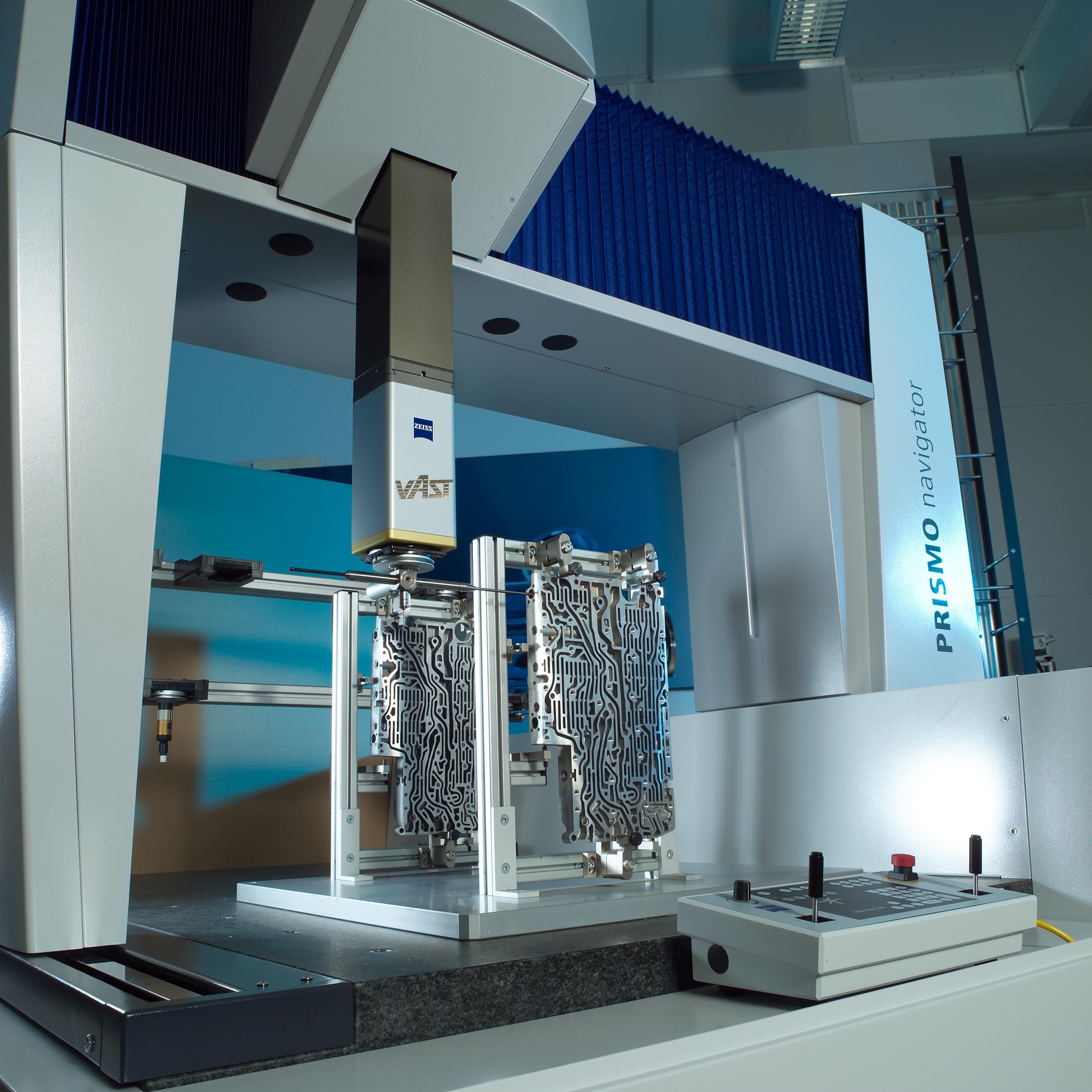

Zeiss Prismo Navigator

The Zeiss Prismo Navigator machine is the latest GOIMEK acquisition, which is aimed at giving better value to its high precision measuring service. One of the most notable qualities of this machine is its high level of accuracy:

- Positioning E = 0.9 + L/350 microns

- Repeatability P = 0.9 microns

- Roundness RON = 0.9 microns

- Rotary table RT 05-400 = UR3.5 UT3.5 UA3.5

- Accuracies in accordance with ISO 10360-4

Furthermore, the three-dimensional Zeiss Prismo Navigator has two different heads. One, the VAST GOLD head for active probing and high-speed exploration and, on the other, the RDS articulated head with XXT probe.

Another of the differentiating factors of the machine is its controlled 4th axis rotary table, which enables highly accurate work and to reach more difficult to access areas making it an excellent machine for rotary workpieces.

GOIMEK´s specialised measuring area

In its facilities, GOIMEK has a specific area for high precision measurement which has the latest generation resources such as the Zeiss MMZ and Zeiss Accura coordinate measuring machines, among others, to which the new Zeiss Prismo has now been added. These resources are located in a controlled temperature room to guarantee measurements with the maximum quality demanded by customers, and they allow a wide range of services to be offered, such as:

- Measurement of parts and assemblies

- Measurement of forms and roughness

- CAD based inspection

- Verification of prototypes and first samples

- 3D inspection (with Zeiss Calypso software)

About GOIMEK:

GOIMEK,a co-operative and part of the DANOBATGROUP specialising in precision machining and large part machining, offers an integrated service that includes the management of the entire supply chain, from the purchase of the raw material to the machining of the part itself, as well as the thermal/surface treatment and painting, to conclude by also offering the verification and certification of the machined part. The business aims its activity at the machining of precision parts for various sectors such as aerospace, machine tools, wind energy and capital goods, among others.

Through its total solution offer, GOIMEK offers its customers the opportunity to integrate all the needs of the machined parts supply chain with high quality and precision requirements.

The production plants are located in the Itziar-Deba industrial estate and on the Goitondo estate in Mallabia. The Itziar plant specialises in the machining of large single and parts, while the Mallabia plant specialises in grinding and machining of complex geometries on demanding materials.