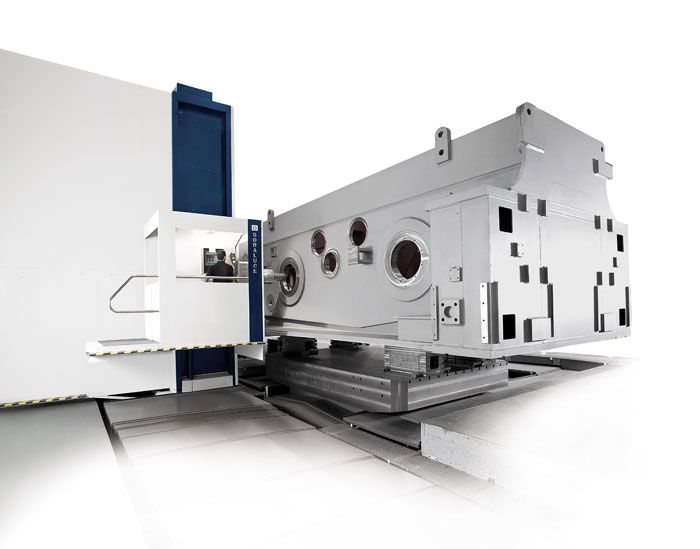

FAGOR ARRASATE improves its large press heads machining process thanks to the acquisition of a SORALUCE floor type milling-boring machine

FAGOR ARRASATE is a world specialists in design, manufacture and supply of forming machine tools, from presses and complete stamping systems to lines for manufacturing, processing and cutting sheet metal or special complete lines for manufacturing complex sheet metal parts. FAGOR ARRASATE has improved its large press heads machining process with the acquisition of the floor type milling-boring machine FX-20000. The machine has allowed the optimisation of the machining process and has reduced cycle times, thanks to a significant reduction in the number of workpiece set-ups , and also to the machine flexibility and the high stock removal capacity of the SORALUCE heads .

CHALLENGE: Press head machining process with minimum number of set-ups .

- Press heads machining process weighting 20 ÷ 150 Tn.

- Pendulum machining: machine downtime = 0.

- Set-up 1+2: Base and upper side machining on floor plate: 4 guideways milling + drilling operations.

- Set-up 3: 4 sides machining on rotary-travelling table: axle bore boring , diameters, various planes milling and drilling operations.

SORALUCE SOLUTION:

- Floor type milling-boring machine FX-20000-W.

- X traverse: 20000 mm / Y traverse: 4800 mm / Z traverse: 1900 mm.

- Spindle power: 71 kW / 2000 rpm.

- Ram Balance.

- Modular quill: Ø 200 mm / W: 1400 mm.

- Customized universal head.

- Rotary-travelling table 5000 x 3500 mm / V : 3000 mm / 150 Tn.

- Floor plate 11000 x 600 mm