DANOBATGROUP presents the latest developments of advanced manufacturing solutions of DANOBAT and SORALUCE at the Metalloobrabotka exhibition in Moscow

-

The machine tool and production system manufacturer will be present at the fair, which is held from 27 to 31 May

-

The group will exhibit advanced technologies for the most demanding industry applications of Danobat and Soraluce brands

-

The company will also present its digital value proposition, made up of in-house developed technologies within the industry 4.0 paradigm

-

Danobatgroup will furthermore highlight the services offered in Russia through its branch office located in Moscow

With the aim of advertising its firm stake in the development of innovative manufacturing solutions, the machine tool and production system manufacturer, Danobatgroup will be another year present at the coming edition of the Metalloobrabotka fair in Moscow.

At the event, the company will showcase Danobat and Soraluce brand solutions designed for carrying out high productivity grinding, turning, milling, boring and metal forming processes of great technical complexity in an exhibition space of 53 square meters in stand 23E55 hall 2.3 .

In addition, the company will avail of this opportunity to share its digital value proposition, composed of in-house technological developments based on industry 4.0 concepts with an aim to advancing in the creation of intelligent manufacturing spaces, fitted with interconnected equipment and capable of autonomous operation.

The industrial group will also present its services in Russia provided by its branch office located in Moscow.

Advanced developments in cutting-edge technology

The group will present detailed information about the most advanced developments in grinding, turning, milling, boring and multitasking processes, as well as new technologies such as laser blanking and advanced solutions for the manufacture of high value-added components for different industries.

During the fair, Danobat will showcase its state-of-the-art grinding solutions for highest requirements applications such as the critical components of aircraft engines and turning solutions for applications for railways and oil&gas industries. The company will offer technologically advanced solutions and services, including among other engineering, consultancy, which are fully adapted to clients’ needs.

Specialists in the supply of advanced solutions for the manufacture and maintenance of critical components of aircraft engines and landing gear, Danobat offers unique solutions for the manufacture and maintenance of critical components of turbines of aircraft engines (rotor, stator, compressor vanes and main shafts) and for landing gear, ensuring compliance with requirements for reliability, production and quality demanded by original equipment manufacturers (OEMS) and leading companies worldwide in aircraft maintenance.

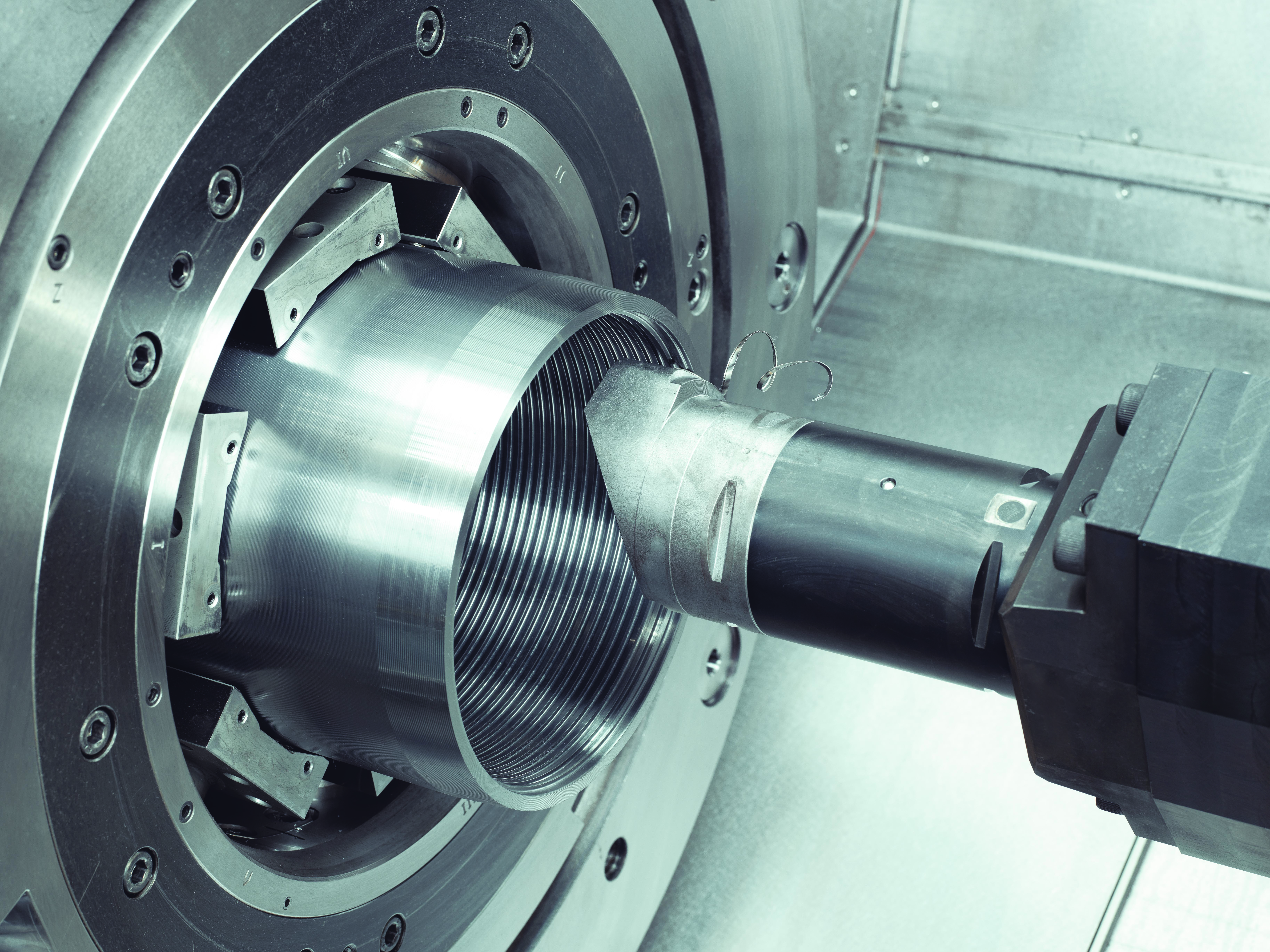

Danobat also offers a full range of solutions ranging from advanced machines to fully automated production lines for the oil and gas industry. The offer includes turnkey solutions for turning couplings and pipes according to international standards, such as PREMIUM, API and GOST for the machining of high-pressure valves, ball valves and valve seat ring.

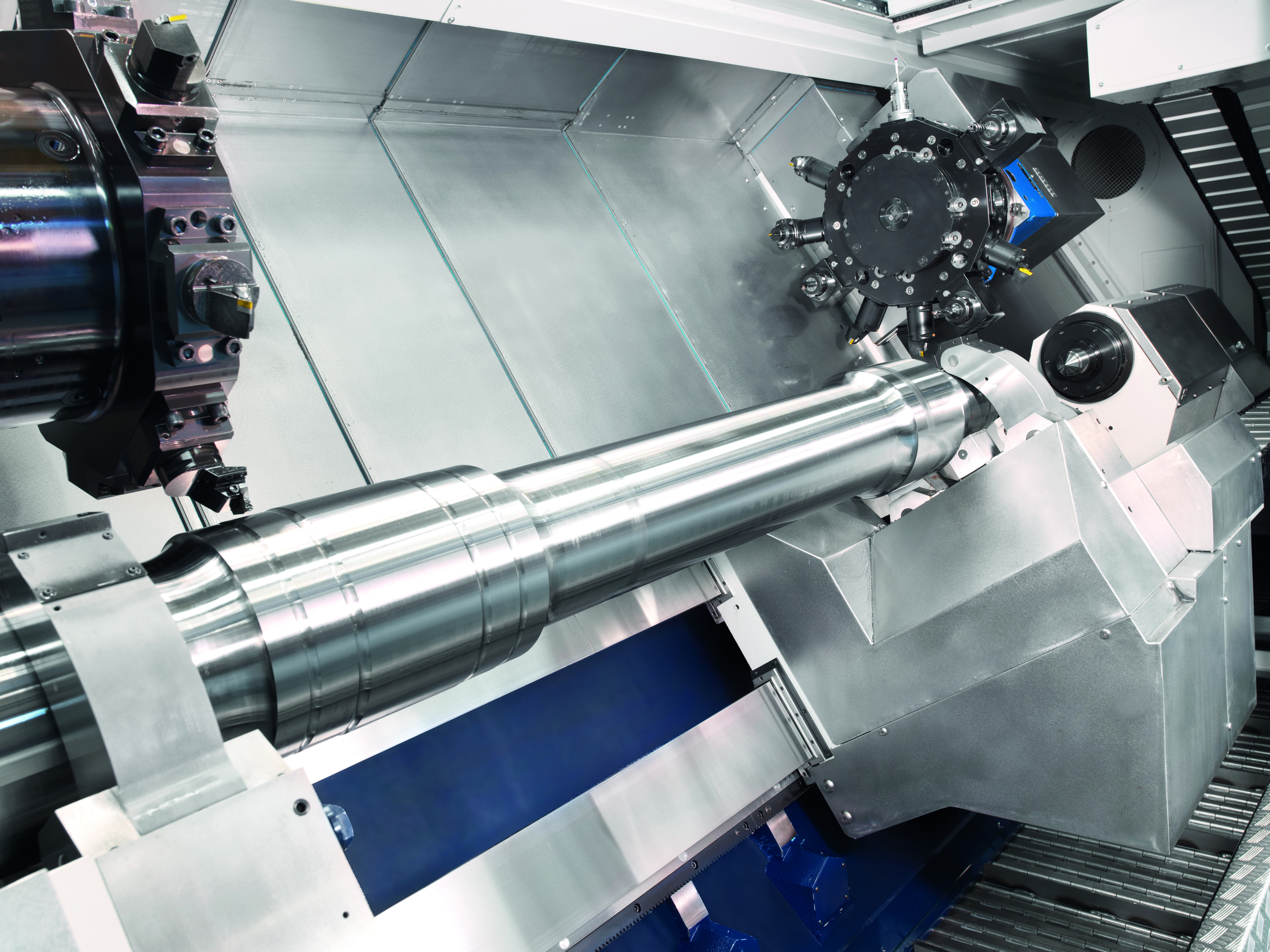

Regarding railway solutions, Danobat offers comprehensive solutions for machining processes, inspection and assembly of axles, wheels, wheelsets, and for preventive, corrective and predictive maintenance of rolling stock. The company has solid experience in manufacturing processes and in the development of specific equipment incorporated with the latest technology that ensure full compliance with production and quality requirements demanded in the railway sector.

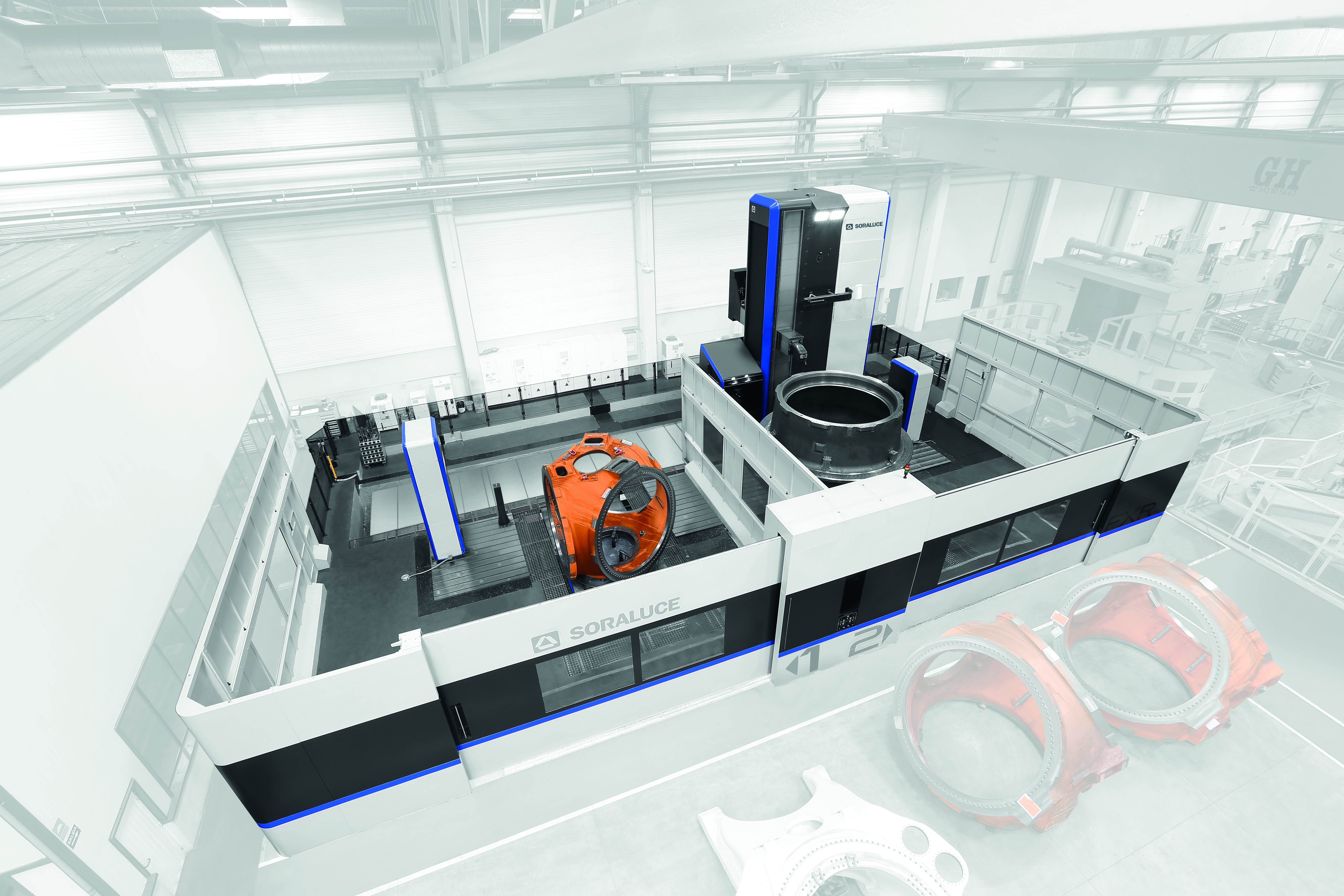

The stand will also include information on Soraluce Milling, boring and multitasking solutions.

Soraluce has one of the most complete and advanced portfolio of products and services in milling, boring and turning on the market, which can also be customised to the needs of each client.

Endorsed by its knowledge and experience in milling and turning technology as well as its position as technological leader in the sector, Soraluce presents the new Portal Series. Soraluce showcases a complete range of portal machines, including mobile table milling machines, gantry milling machines, multitasking machines, with fixed and moving cross beams, with a full range of heads and other options.

Soraluce also provides multitasking solutions, which allow different machining operations to be integrated into one single machine, making it possible to reduce cycle times, save on costs and increase the efficiency of the machining processes. Soraluce has reshaped the concept of “multitasking”, traditionally associated with the integration of turning and milling in one machine, thanks to the development of advanced technologies which allow the addition of grinding. This last operation is the phase which requires the highest level of precision during the machining process and the one which concludes the manufacturing of high added value industrial components. The multitasking concept developed by the company, can be incorporated into the entire range of the manufacturer’s machines.

As such, Soraluce focuses on developing technological solutions for different customer requirements which drive efficiency and productivity to its limits.

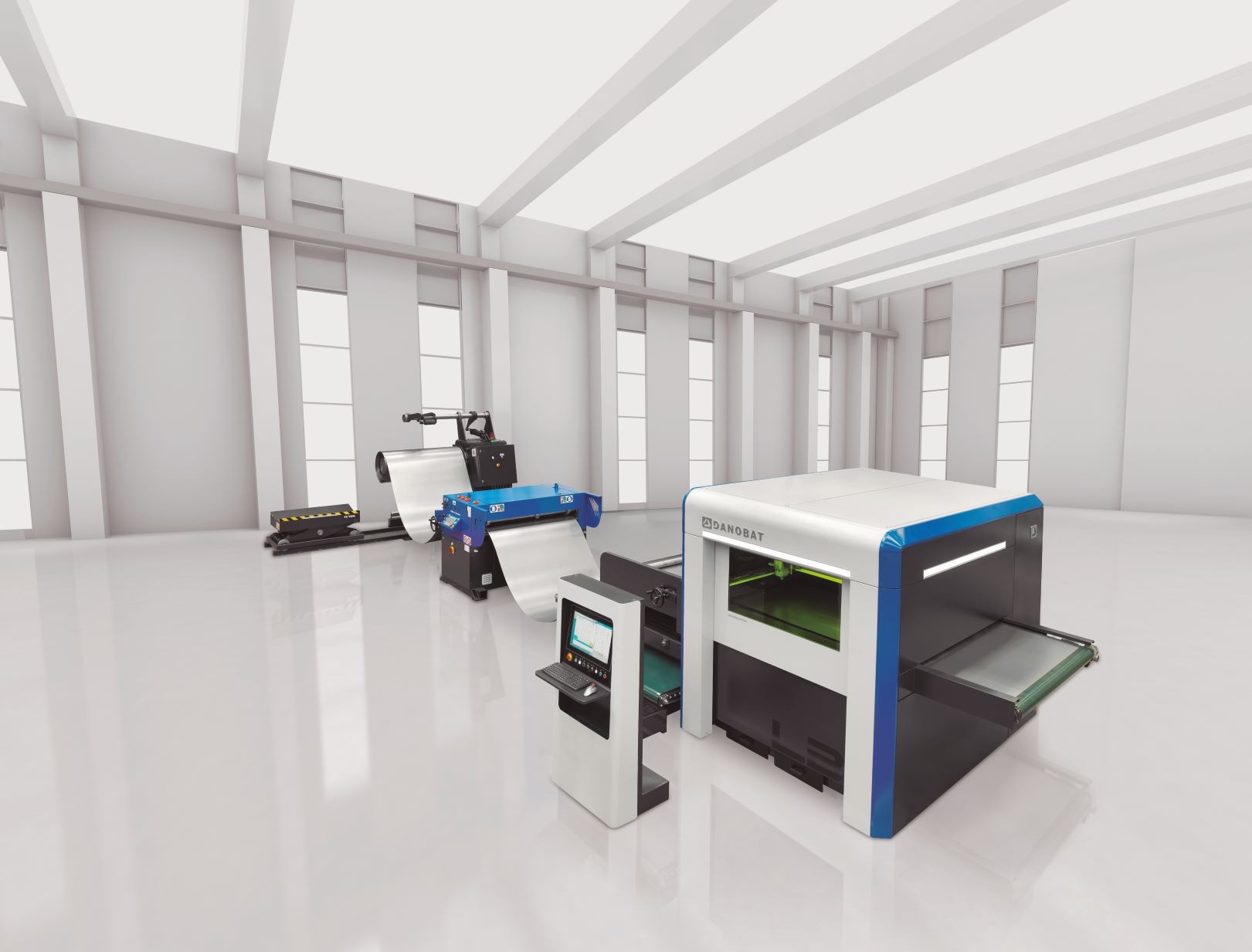

Apart from the above mentioned information, and regarding sheet metal solutions, the stand will also provide information about the new Danobat LB coil-fed laser cutting machine. This is a high-productivity solution that combines all the advantages of fiber technology applied to laser cutting (efficiency, speed, versatility, minimum maintenance, etc.) with the benefits of metal coils (savings in material costs of up to 15% and a more efficient use of sheet metal).

The main objective of this concept is to make significant savings in the material to be transformed and a considerable increase in productivity deriving from the reduction in machine downtime. This new solution can be used for applications such as cookware, service centers and tanks.

Digital technologies for the factories of the future

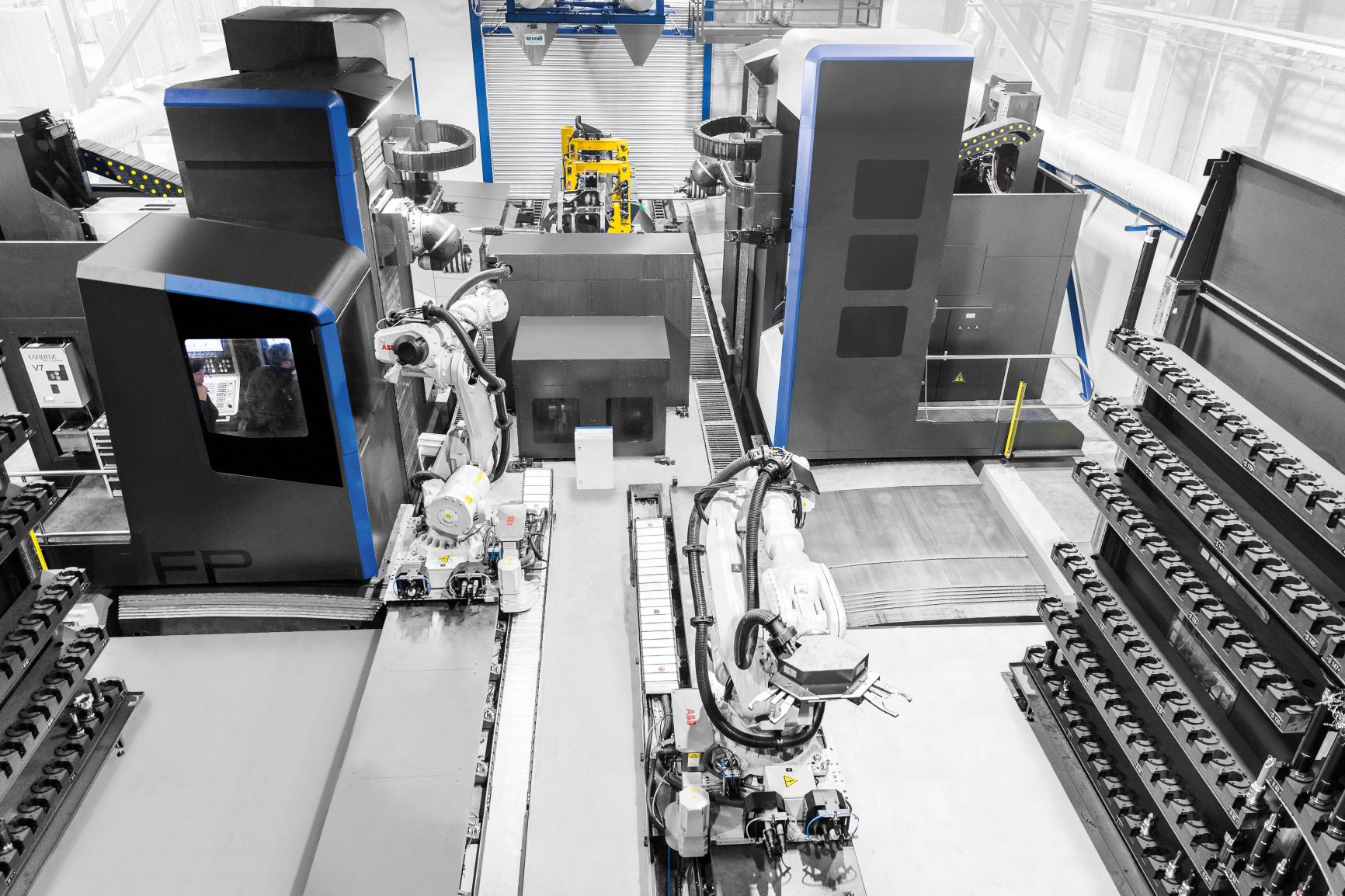

During the course of the fair, Danobatgroup will explain its focus on industrial digitalisation, which is structured around an offer of intelligent developments using digital technologies, with an aim to forge ahead in the automation of real manufacturing environments.

The latest technological advances make it possible to offer new high value-added services and, in this context, Danobat and Soraluce will use Metallobrabotka to showcase their offer in servitization aimed at offering intelligent machine management, improving maintenance strategies, increasing the competitiveness of equipment and optimising the production of manufacturing plants.

Within its services branch, both brands have a consolidated digital value proposition, based on the latest advances in information and communication technologies, with the aim of facilitating the construction of smart, interconnected, automated factories and manufacturing environments capable of independent decision-making.

The above has already become a reality and the technology has been incorporated on machines and complete production lines in different industrial sectors, which are operational in different parts of the world.

The digital services that Danobat and Soraluce present at Metalloobrabotka include the Smart HMI, an intelligent interface that offers assistance in the operation of the machine and allows access to information on the status of the equipment and its operation in real time.

The main advantages of this service are the increased availability of the equipment, the logical operation of the control, the programming aids and the presentation of specialised machining cycles as well as documentation on operation and maintenance on screen.

In addition, it offers facilities for assisted maintenance, such as troubleshooting aids and recommended recovery plans, as well as graphical information on energy consumption.

The commitment to digitalisation on display at the fair also includes the Data System, a set of services based on technology using Big Data and data pick-up and monitoring systems that provide info on machine status, anticipate failures, plan stops and improve the productivity of equipment.

The Data System is another of the digital solutions consolidated by the industrial group which has been installed on equipment of manufacturers belonging to different industrial sectors and that comes in very handy for aspects such as controlling the real consumption of the machine or the optimization of the efficiency of the production management and of the machining processes, among others.

The capacities of the Control System will also be presented at Metallobrabotka. This is aimed at the management of automated manufacturing lines, focusing on bringing together all control processes to facilitate decision-making based on knowledge of the status of equipment and from a central information hub.

The Control System also enables the monitoring of key data and indicators, generation of reports and information to optimise processes and increase safety, among other advantages.

Finally, the manufacturers will present Intelligent Components, intelligent devices fitted on the machines to improve the productivity or machining capacity of the equipment. Within this family of solutions is the DAS+ active damping system developed by Soraluce, which has already been installed on some 70 machines.

With the Russian market in the spotlight

Danobatgroup will also present its added value services in Russia. Danobatgroup´s team in Moscow aims to position its two top brands - Danobat and Soraluce - among the most prestigious on the Russian market. In order to achieve this purpose, the manufacturer branch office in Russia has a specialized local technical team that provides efficient and close-by technical assistance and services from Russia to Russia. This commitment allows the company to strengthen ties with its customers and offer a more nearby local service, which at the same time is specialised and with a greater added value.

About DANOBATGROUP

With 65 years of experience in the field of technologies applied to industrial manufacturing, Danobatgroup has a staff of over 1,300 highly qualified people around the globe. The group is an international benchmark in the sector of machine tools and technologies applied to industrial manufacturing.