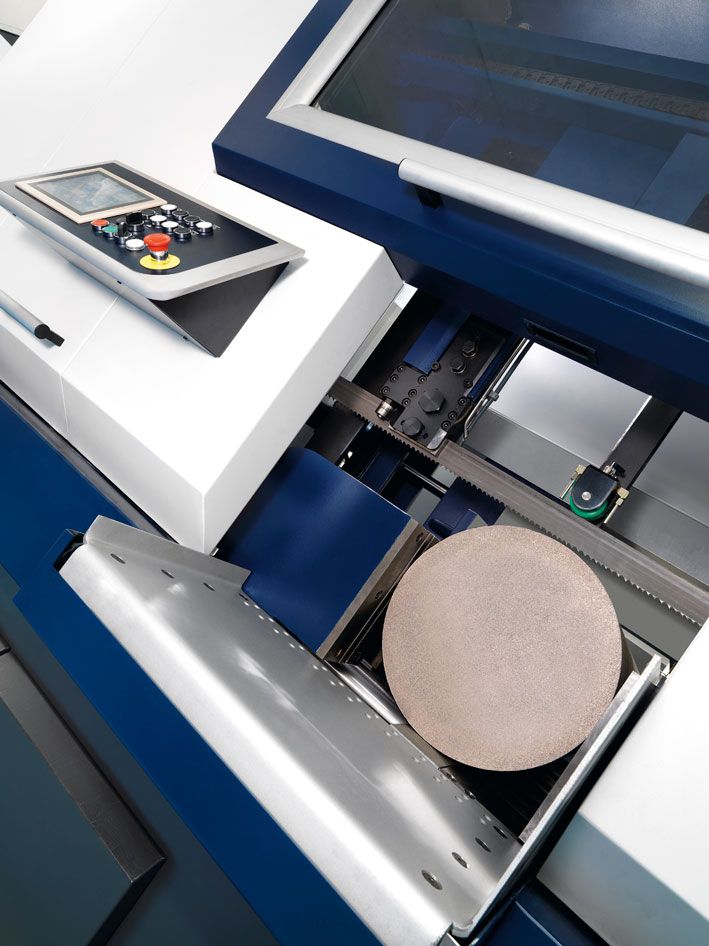

Danobat creates iSOFT to maximize band sawing production and blade life

Danobat has created the iSOFT control system for band sawing machines. This new system allows companies to achieve maximum production rates together with optimum blade life. Nowadays, it is the operators “experience' that decides what speed the blade runs at and the also decides the downfeed rate of the machine, which means it is the saw operator that dictates overheads in terms of blade life and blade costs.

This means that the most important factor that influences in the cutting efficiency is the operators experience. Danobat has introduced the iSOFT control system to solve it. By simply selecting different options in a very simple screen the machine works automatically with a higher reliability than any human being. Among different options the user can find variables such as: material grade, so once choose among carbon steel, stainless steel, nimonic or non-ferrous materials, solid or tube, the machine will automatically set its own parameters in terms of cutting rates and blade speed and will continually adjust itself, depending on the cross section of material and the blade condition. While most material specifications are pre-programmed into the iSOFT, there are spare programs so that companies can add their own specific material groups, if required. Another unique feature is automatic “running-in' of a new blade, whether it be bi-metal, carbide or a new blade. This is an area that tends to be neglected and results in premature blade failures. With the Danobat system, it not only eliminates the guess work, but allows the operator to input a specific make of blade to ensure that the correct running-in procedure is being followed. The machine will also calculate the weight of each cut component and display that weight on the control console. The result of the iSOFT is maximum production and optimum blade life.