Advanced grinding solutions for the automotive industry

All over the world the automotive industry is evolving technologically thanks to investment in the development of electric and hybrid vehicles. This has led Danobat to develop new grinding solutions for manual and automatic gearboxes.

Whether vehicles use combustion engines, hybrid or purely electric motors, the trend in the automotive industry is the same: to create more efficient vehicles to increase performance and reduce fuel consumption.

The industry is also characterised by a need for machinery to be highly flexible so that it can be reconfigured quickly. Customers are tending more and more to ask for systems to be more flexible, so as to cater for the production of wide range of references in different gearboxes even within the same vehicle model.

Danobat has been working with leading vehicle manufacturers for decades, developing productive and reliable solutions. Danobat machines use natural granite beds, linear motors on all main axes and drives featuring built-in motors on the B-axis and on workheads.

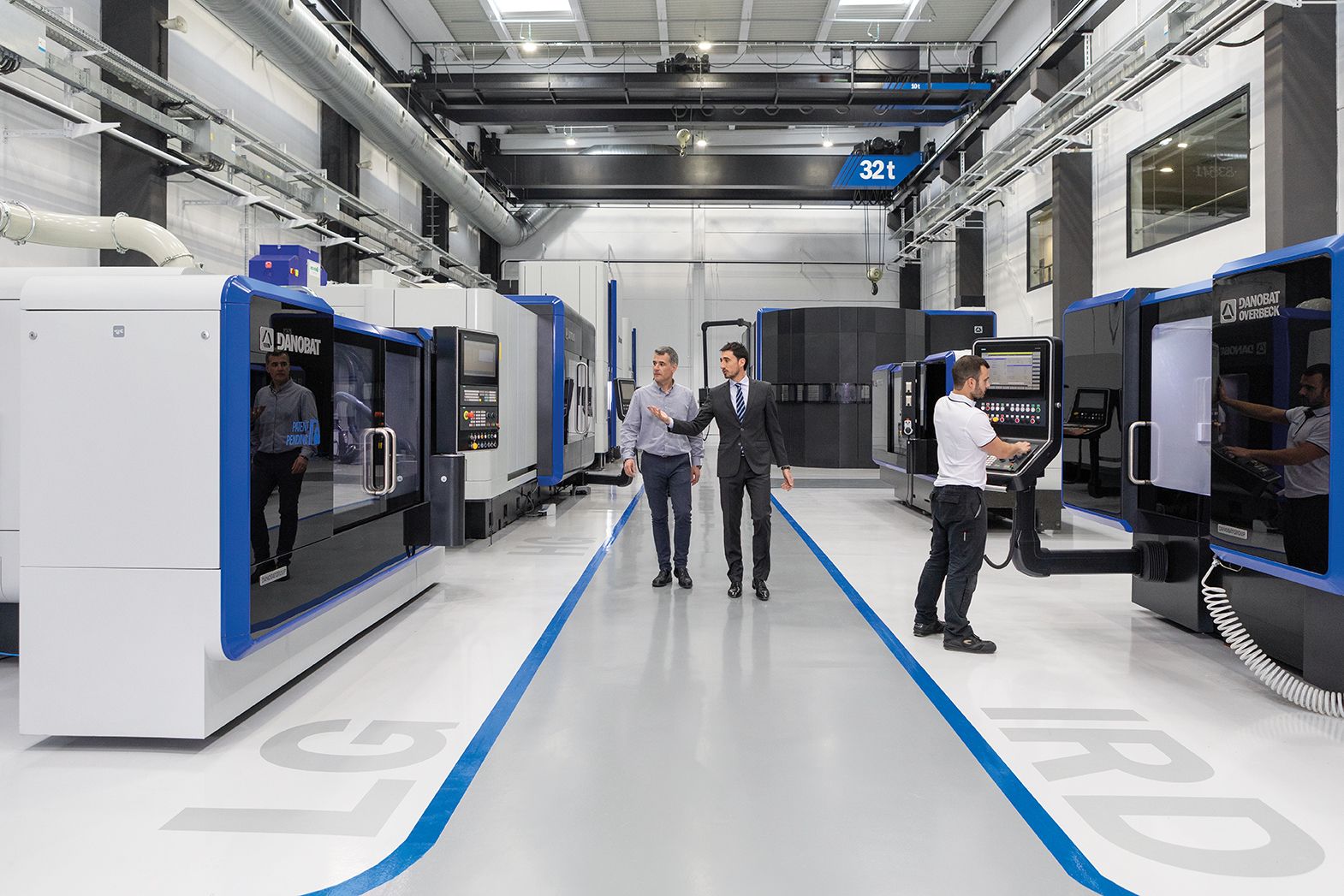

A network of centres of excellence for generating high value-added solutions

Danobat has a network of centres of excellence in grinding and machining for the manufacturing of precision parts. This cutting-edge initiative is unique in the field of grinding, and enables customers to become more competitive, with the highest standards of efficiency and productivity.

The company has developed high value-added solutions tailored to meet the needs of each customer in the transmissions sector. Ongoing cooperation between supplier and customer is essential if a comprehensive solution to the customer´s needs is to be generated. This calls for proactive listening on the part of the company´s technical and sales teams.

Danobat’s catalogue features solutions designed and developed to carry out grinding operations, with uninterrupted operation and improved productivity, from machine setup to the automation of workpiece loading and unloading, ensuring easy integration into production lines. Danobat machines are designed to provide increased productivity, with the possibility of working three shifts.

These solutions are characterised by the high quality and extreme reliability of their components, achieved thanks to cooperation with first-tier suppliers while at the same time stressing the in-house development and manufacturing of components as an essential factor to ensure the immediate availability of spare parts.

The wide range of solutions offered, allow to develop a great variety of applications in the automotive field, from the manufacture of transmission shafts to pump shafts.

Precision: a key factor for transmission components

For the automotive industry, Danobat has developed solutions for the manufacturing of various gearbox models for conventional, electric and hybrid cars (CVT, AMT, DCT, AT and MT).

Transmission components are key in ensuring greater efficiency. They must meet very strict machining tolerances, especially those designed for electric vehicles. This means that there is increasing demand for more and more precise machine-tools.

Digital technologies and automation

Cycle times are very tight, which means that there is a need for automation and control systems for plant management.

Danobat integrates technological advances in communication and information. Those advances are focused on developing in-house solutions with advanced technologies that enable production lines to be controlled via continuous remote monitoring of the entire system, so that the status of machinery is known at anytime and anywhere.

Demand for turnkey lines is increasing among vehicle manufacturers, and automation has a vital role to play. Danobat meets that demand via systems built into its machines, with integrated gantries and robots. For example, the company has researched, developed and supplied complete lines for manufacturing the components that make up the CVT.