SORALUCE participates in the consortium for the development of the European project MC-SUITE

It searches to increase the competence of the European manufacturing industry, reducing the gap between the programmed process and the real part.

The MC-SUITE project proposes a new generation of ICT (Information and Communication Technologies) which enables process simulation and optimization of tools enhanced by physical measurements and monitoring, thus reducing educes the distance between the virtual and the manufacturing process.

The advances in the Information and Communication Technology (ICT) are revolutionizing our everyday life. However, the manufacturing industry has not taken complete advantage of this huge potential yet. The final aim of the MC-SUITE project is to open the doors of the manufacturing workshops to this new revolution. Indeed, the MC-SUITE project consortium strongly thinks that the current ICT can have a tremendous impact in the productivity increasing the competence and expertise of the European manufacturing companies and especially the SMEs.

It searches to increase the competence of the European manufacturing industry, reducing the gap between the programmed process and the real part.

The MC-SUITE project proposes a new generation of ICT (Information and Communication Technologies) which enables process simulation and optimization of tools enhanced by physical measurements and monitoring, thus reducing educes the distance between the virtual and the manufacturing process.

The advances in the Information and Communication Technology (ICT) are revolutionizing our everyday life. However, the manufacturing industry has not taken complete advantage of this huge potential yet. The final aim of the MC-SUITE project is to open the doors of the manufacturing workshops to this new revolution. Indeed, the MC-SUITE project consortium strongly thinks that the current ICT can have a tremendous impact in the productivity increasing the competence and expertise of the European manufacturing companies and especially the SMEs.

The consortium assembled for this 36-month project consists of a unique combination of skills and expertise including 6 SMEs (Small and medium-sized enterprises), 2 universities, 2 research centres, and 2 large companies. Both SORALUCE and its technological partner IK4-IDEKO participate in the project. Hence, this consortium covers all the value chain of the manufacturing products including software providers, equipment providers, machine tool builders and end users.

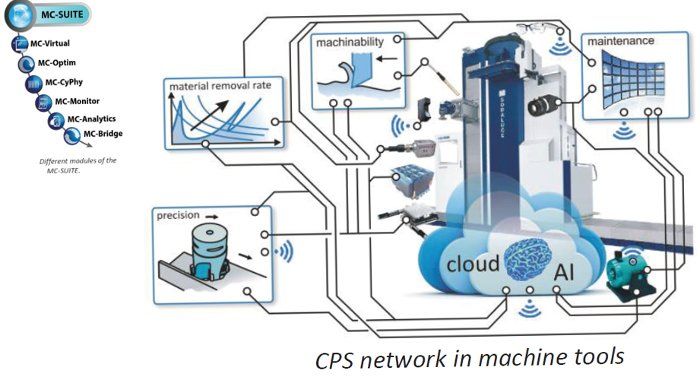

The aim of the project is to develop the MC-SUITE application based on six different modules ready to reduce the gap between the simulated and the real process.

- To develop a virtual model of the machining process. MC-Virtual obtains the final path of the tool and the quality of the real part, the cutting force and process stability, overcoming the limits of the actual Computer Aided Manufacturing software.

- To apply multi objective optimization methods in manufacturing processes. MC-Optim optimizes the milling process considering multiple objectives including productivity, quality.

- To create a complete Cyber Physical System for machine productivity improvement. MC-CyPhy includes three different embedded systems connected to the virtual model and to the monitoring system to increase the productivity.

- To build up a monitoring system based on the cloud. MC-Monitor is a cloud based system able to store heterogeneous data including signal coming from internal sensors of the machine, from embedded systems and operator authored data.

- To create new services based on Big Data. MC-Analytics is a platform to treat the information of the cloud for predictive maintenance and productivity improvement.

- To combine simulated and experimental data in a complete software suite. MC-Bridge compares the results of the virtual model with the real ones obtained from the monitoring system. This way on-line and off-line optimizations are performed both on the simulations and on the machining process.

As the CPS (cyber physical systems) solution integrator, SORALUCE is responsible for the demonstration phase of MC-SUITE solutions as laboratory and industrial demonstration.

From one side, SORALUCE participates in the definition of the requirements of the project in terms of ICT technologies and manufacturing technologies. As end user SORALUCE is defining the process targeted by the project including the main characteristics and expected improvements.

Since SORALUCE milling, boring and turning machines are used to develop Cyber Physical Systems able to improve drastically the machining process, they are important players in machine tool design issues related to the CPS and embedded systems. Links between the embedded systems, the simulation, the optimization and the manufacturing machines will be developed to obtain a complete network. It will broaden the potential of Cyber Physical Systems in several dimensions; including self-tuning, auto-diagnostic, coordination or efficiency.

As machine tool builder and service provider SORALUCE will define new wave remote service capabilities related to cloud solutions. The objective is to treat the large amount of data recorded in the monitoring system based on the cloud to allow optimizing the process, constructing advanced analytics, realizing remote diagnostic and maintenance. The continuous monitoring of the process will allow detecting rapidly the deviations from the reference situation hence avoiding loss of productivity using: Remote and early stage component failure detection for accurate predictive maintenance, Remote process monitoring and diagnostic via hotline assistance, New cloud based services.

Finally all the developments will be validated against a chain of experimental demonstrations of increasing complexity leading up to three realistic test case demonstrations by the three main end-users: Goimek as specialists in big size precision part machining with a floor type milling boring machine SORALUCE FR, Aeromec focused on machining of parts for aerospace, energy generation and machine tools with a SORALUCE floor type milling machine SORALUCE FL and DIAD GROUP, as is a leading company in optimizing customized process and design and testing of advanced materials and components for aerospace and automotive sectors with machining centre.