2017 OPEN HOUSE in DANOBAT-OVERBECK

-

DANOBATGROUP will open its doors in order to offer a unique opportunity to customers and other visitors to witness its latest developments and technologies on-site.

The DANOBATGROUP will develop its 2017 OPEN HOUSE from April 26th to 27th at its manufacturing plant in Herborn (Germany).

-

DANOBATGROUP will open its doors in order to offer a unique opportunity to customers and other visitors to witness its latest developments and technologies on-site.

The DANOBATGROUP will develop its 2017 OPEN HOUSE from April 26th to 27th at its manufacturing plant in Herborn (Germany).

The 2017 OPEN HOUSE will offer the opportunity to show the technology behind DANOBAT-OVERBECK and DANOBAT machines, as well as new developments applied to its wide range of grinding machines. Some of these developments will be showcased in real machining conditions by the best specialists in these technologies.

The visit will consist of a guided tour at the company´s facilities to discover its ambitious project, based on cutting edge technology, knowledge, innovation and advanced solutions. In addition, selected suppliers will show their products while providing information on related matters.

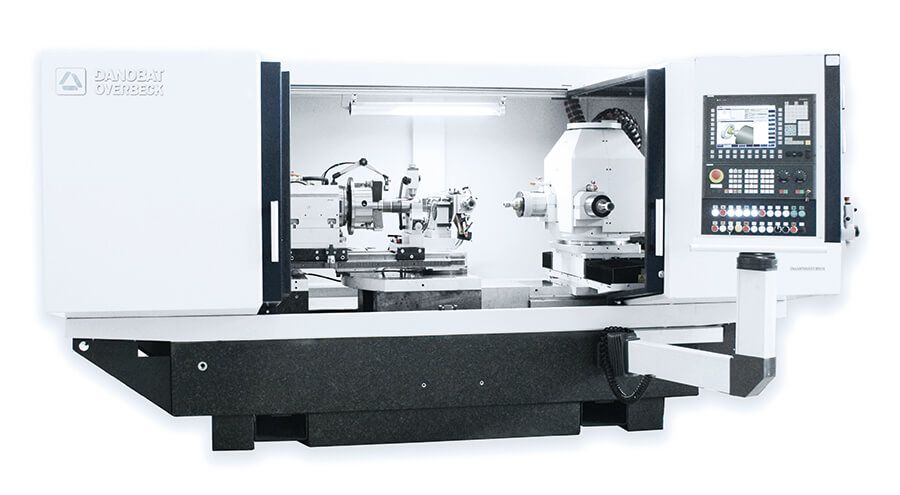

Among many other machines, the firm will exhibit the new ILD series, which is the latest solution for internal grinding and meets the most demanding requirements for large workpieces. The ILD internal universal grinding machines provide high-precision tool machining for internal, external and face grinding of large workpieces, up to 1300 mm long or until a work swing over table of up to 760 mm. Perfect for grinding of spindle housings, shafts, tool holders, roller bearings, hydraulic components and machine tool components using the latest technology. The powerful and user-friendly DANOBAT-OVERBECK software includes an intuitive interface, optimally adapted to the machine as well as to the requirements of the customers. The non-round grinding, jig grinding, simulation, CAD-CAM machining module and other options complete the software possibilities of this product line.

The goal of the companyis to improve the quality and working time of your workpieces by means of high technology and tight customer-supplier relationship.