DANOBATGROUP offers sustainable production systems

The tendency to energy eficiency represents the beginning of a paradigm shift for the machine tool sector. For a long time, the machine tool industry has been driven by the motivation to provide the most productive, the most precise and the most reliable machines to customers.Competitiveness has been deined and determined by manufacturing excellence. In the last few years, however, the machine tool sector has begun to invest in sustainable machinery since it has been proved that optimizing the design, the energy consumption and reducing material waste can have a positive effect on lifecycle costs of machine tools, improving the productivity and competitiveness of the machine.

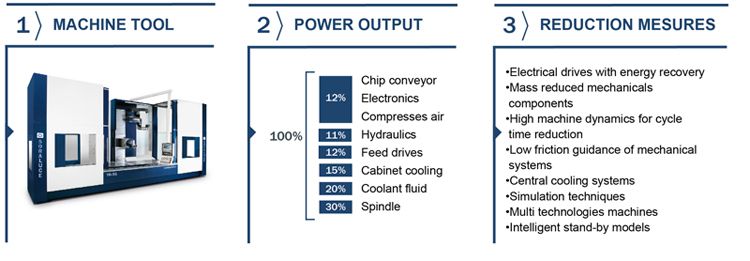

The world paradigm is changing and the machine tool sector has to face the new global social and economic challenges too. The constantly growing energy consumption, associated with more CO2 emissions and overuse of natural resources and raw materials, endangers our society. Besides, the market demands require increasingly sophisticated machines to manufacture workpieces increasingly complex, with higher quality in less time. In order to face these new global social and economic challenges DANOBATGROUP innovates and progress through new developments and projects that boost the sustainability of its products, designing new machine concepts that are optimized and that include more eficient components, which lead to higher performance of machining processes. For DANOBATGROUP increased competitiveness and sustainability go hand-in-hand. Putting stronger emphasis on eco-eficiency does not represent a shift away from traditional elements of competitiveness such as precision, speed or reliability, safety or ergonomics. What is more, for DANOBATGROUP this approach is the key to ensure the manufacturing excellence for the upcoming decades. DANOBATGROUP is currently working on different sustainability research areas to increase the energy eficiency on machines, to ind new solutions to face the scarcity of resources and avoid emissions, and to increase safety and work quality of machine operators through smarter control systems and tools. Solutions to improve the energy eficiency Machine designs are based on minimized material weight of moving machine components. Stiffness of a structure is guaranteed by high dynamic axiscontrol functions, which saves the energy consumption. DANOBATGROUP is developing and implementing cutting-edge solutions in different areas:

- Energy management: CNC stand-by options, regenerative braking

- Eco-design: less weight components

- Eficient machining process: integration of operations

Solutions for scarcity of resources and avoiding emissions Optimized process cycles based on more sophisticated technology support, shortens machining time and save coolant and lubricant use, waste chips and energy consumption. DANOBATGROUP implements an intelligent machining planning from the beginning of the life cycle of the equipment, deining the most appropriate production design in order to minimize the environmental impact. New developments that DANOBATGROUP is currently implementing on machines:

- Eficient cooling systems: good sizing of cooling unit, MQL , cryogenization, nozzle design

- End of live management: material re-use, eficient components

- Simulation and modelization in order to save machining time, space occupation and tools, and avoid collisions

- Less environmental contamination: noise, pollution and emissions

Solutions for social sustainability DANOBATGROUP machines incorporate smart control systems that help to operate and maintain the machines. These systems make the machines easier to use, and increase safety and work quality, boosting the work and life quality of machine operators. Research and implementation areas:

- Context-adaptive assistance for fault diagnosis

- Mobile, personalized tutoring systems

- Location-based. Maintenance and planning assistance

- Assistance in complex work processes

- Human-machine interaction