SORALUCE shows in BIMU 2016 its technological leadership

The European brand presents in BIMU 2016 fair the new generation of SORALUCE milling, boring and turning machines and the innovative DAS System (Dynamics Active Stabiliser), which is set to be a revolution in the machine-tool sector.

The New SORALUCE Generation is based on a complete revision of the machine from the user’s point of view focusing on improving operation efficiency and developing a Total Machine Concept that takes into account the machine but also the complete working area. All the interactions of the operator with the different machine elements are analysed for an optimal implementation. The evolution taken in design makes it easier to operate and maintain the machine. SORALUCE has launched onto the market a new generation of machines, which have a more ergonomic working environment and maximum protection for the operator. SORALUCE has recently been awarded with the Red Dot Award for its innovative design.

The European brand presents in BIMU 2016 fair the new generation of SORALUCE milling, boring and turning machines and the innovative DAS System (Dynamics Active Stabiliser), which is set to be a revolution in the machine-tool sector.

The New SORALUCE Generation is based on a complete revision of the machine from the user’s point of view focusing on improving operation efficiency and developing a Total Machine Concept that takes into account the machine but also the complete working area. All the interactions of the operator with the different machine elements are analysed for an optimal implementation. The evolution taken in design makes it easier to operate and maintain the machine. SORALUCE has launched onto the market a new generation of machines, which have a more ergonomic working environment and maximum protection for the operator. SORALUCE has recently been awarded with the Red Dot Award for its innovative design.

SORALUCE DAS system is set to be a revolution in the machine-tool sector. It consists of a device that actively increases the dynamic rigidity of machines, thus increasing cutting capability by up to 300% due to the reduction of the risk of chatter during machining process. The system increases cutting capability in general, improves surface quality and reduces the risk of tool breakages, increasing tool lifetime under extreme conditions. The DAS system has won Quality Innovation of the Year 2015 and Best of Industry 2015 awards.

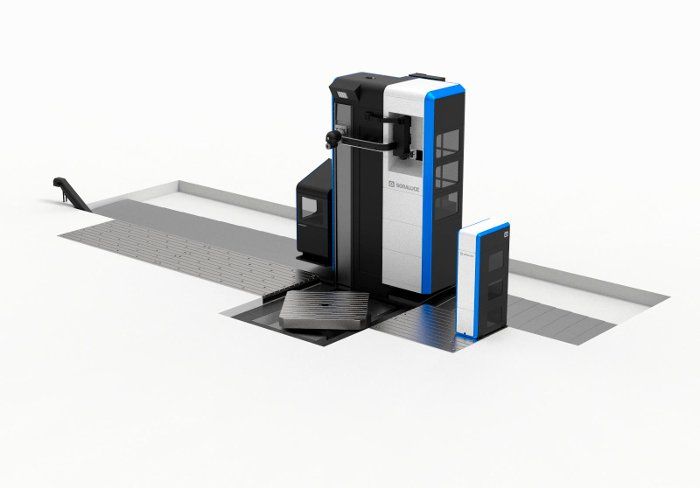

SORALUCE FR-14000 floor type milling boring machine

SORALUCE showcases the new SORALUCE FR-14000 floor type milling boring machine, a multi-purpose milling-boring machine, offering high versatility and productivity for large component machining, becoming a multi-purpose milling boring machine.

The new generation of SORALUCE FR machine is the expression of SORALUCE’s values: reliability, precision and competitiveness. Within these concepts, customers find huge improvements in maintenance, ergonomics, high dynamics and safety in the work environment. Its rigid stable design provides the highest precision and productivity benefits when machining large components.

The SORALUCE FR-14000 milling boring machine is ideal for several applications in different sectors such as Energy (wind and gas turbines), Shipyard, Capital Goods or Precision Engineering, ensuring the highest precision, productivity and reliability for heavy duty components and extremely complex machining operations. It is highly versatile, as it allows a wide range of configurations.

Its rigid stable design provides the highest precision and productivity benefits when machining large components. The machine offers high performance machining results thanks to its high dynamic driving system and a combined guiding and damping system besides offering the proven optimum in power and cutting speed capabilities.

The machine modular design offers remarkable versatility and can be equipped with a large number of optional accessories and wide range of milling-boring heads, enabling the machine to be adapted to customer’s needs with high efficiency and precision. Furthermore, as it is a floor type machine, the work area can be configured according to the specific needs of each customer, with one or several workstations, which makes it possible to carry out simultaneous machining and part preparation operations. It can integrate: floor plates, angle plates, auxiliary tables, rotary or rotary-travelling milling tables and turning tables. The machine responds to multitasking and versatility requirements likewise the demand for finishing workpieces in a minimum number of set-ups.

Thanks to its flat longitudinal axis design and low profile column connection, the machine centre of gravity is kept very low, enabling high machine stability, reduced foundation costs, improved machine operation and ergonomic maintenance.

The machine has 4500 mm vertical traverse, 1900 mm cross traverse and 55 kW spindle power and is equipped with rotary-travelling table of 2500 x 3000 mm and W: 2000 mm with capacity for 40 Ton workpieces. It is provides high level of automation with automatic head changing system and tool changing system.

Additionally the machine incorporates the latest technologies developed by SORALUCE such as the DAS system and Ram Balance, the Dynamic CNC Ram Balance System, patented by SORALUCE, that takes care of ram geometrical accuracy, straightness and parallelism, when crossing vertical and cross axes.

All these technologies of the SORALUCE new generation are integrated into the new control Heidenhain TCN640, a multifunction control where SORALUCE incorporates its know-how in technologies, developments, and applications solutions for precise control and reliable machining.

The milling-boring machine SORALUCE FR-14000 is also a 4.0 machine, with a complete monitoring package based on cloud computing. We can connect to the machine from any location and control the situation in real time with machine indicators such as program in course, used tools, axes and spindles speed, etc.

The wide range of SORALUCE milling-boring heads machine offer a customized solution for each application-operation and automatic change of heads and tools minimizes downtime.

The milling-boring multi-function machine is an advanced technology solutions that provides exceptional versatility, high performance and high production levels. It is reliable, rigid and flexible, allowing easy and quick adaptation to different machining operations and type of machine parts.