We are synonymous with innovation, a characteristic rooted in our DNA

This characteristic shapes our identity, transforming the calling to consistently lead and foresee future challenges into one of our core traits. Innovation fuels our growth and establishes us as a leader in our industry.

“Technological innovation sets the group's businesses apart from our competitors and is key to tackling projects that go beyond the conventional. This instils confidence in our clients as we collaboratively tackle their most ambitious challenges. ”

Director of Innovation of Danobatgroup

Innovation in figures

Investment in R&D

Of our people are involved in R&D related activities

Patent families

Running R&D projects

Key lines in innovation

We focus on the following technological lines, to move towards the autonomous, smart and sustainable factory of the future.

We strive for maximum energy efficiency and drive innovation with a commitment to zero defects. Our focus is on avoiding errors and providing technological solutions that ensure flawless part manufacturing from the very first attempt.

At our core, we prioritise energy efficiency, incorporating sustainable design principles. Our commitment extends to minimizing coolant and resource consumption, fostering recyclability, and promoting the reuse of components at the end of their life cycle.

We leverage cutting-edge artificial intelligence techniques for predictive maintenance, optimizing processes, and proactively addressing potential issues to ensure precision and reliability, avoiding errors and breakdowns.

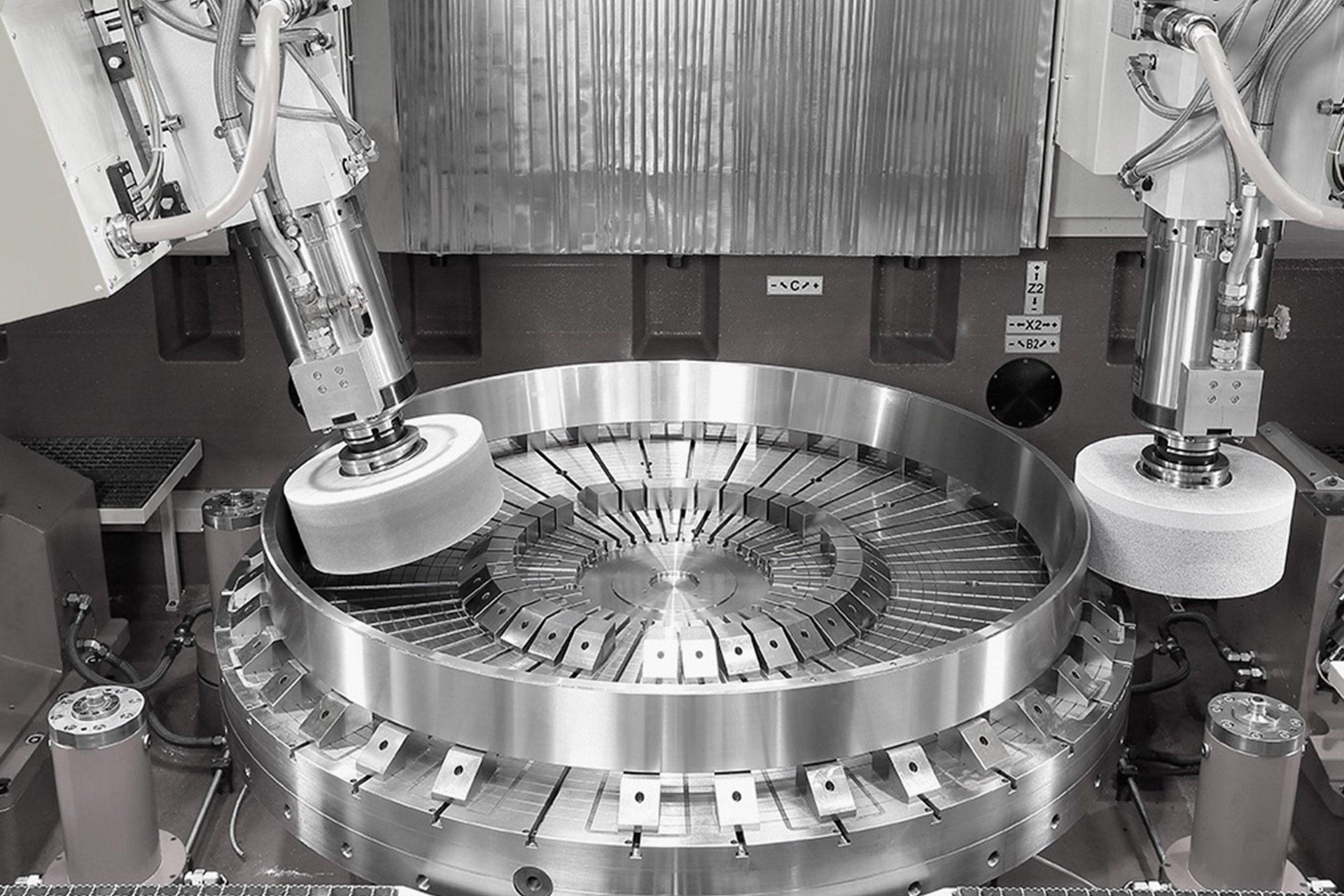

In our pursuit of excellence, our highly specialised companies develop machines, systems, and processes following stringent precision manufacturing processes to the strict quality standards of our customers.

Our experts delve into thermal variations, calibration, volumetrics, and hydrostatic and hydrodynamic lubrication, static, dynamic, thermal and multi-physical calculations, approaching the complete design cycle from the perspective of precision.

The digital era has ushered in increased automation of industrial solutions, posing new challenges for machine tool manufacturers.

Over recent years, we have undergone a significant digital transformation, resulting in a broad range of digital solutions—both hardware and software. These solutions harness the valuable operational data of our equipment, combining the latest AI techniques to meet evolving market needs.

We seek to introduce machining alternatives that provide a differentiating factor and a competitive advantage in production to end users through the use of new cooling technologies or through implementing new tools and manufacturing cycles.

Our use of cutting-edge management and organisational tools, such as simulations of production processes, enhances efficiency, reduces manufacturing costs, improves quality, and ensures safety.

Our commitment to innovation extends to improving the dynamic behaviour of machines and manufacturing processes. We address vibration issues through dynamic machine and drive design, coupled with specific development solutions to eliminate noise and chatter in a variety of machining processes.

Ideko, our innovation engine

More than 35 years ago, Danobatgroup companies decided to create a technology centre that would be the driving force of innovation for all their companies.

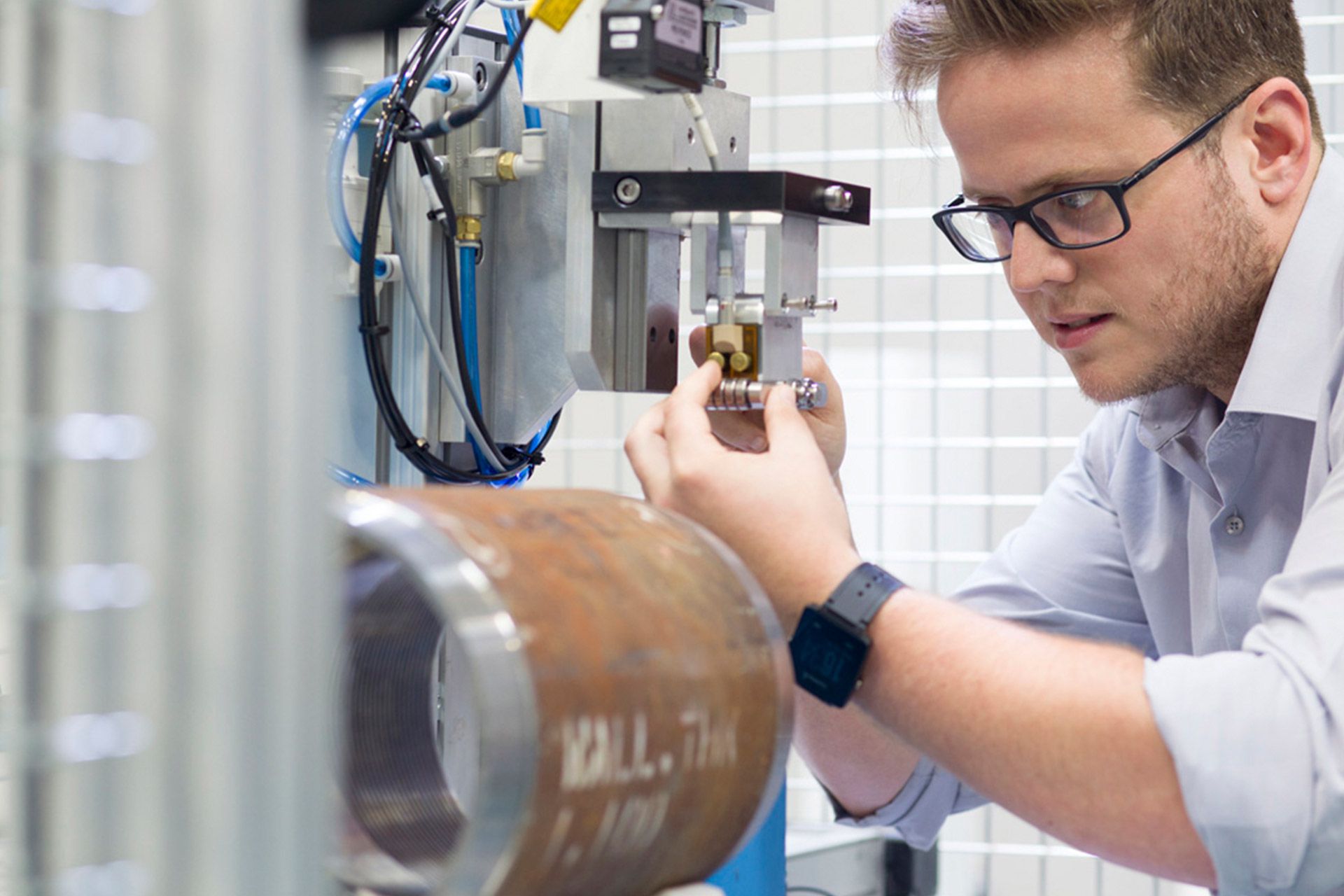

Since then Ideko, a key player in the Basque science and technology network, has been leading innovation in the machine tool and advanced manufacturing sector, transforming technological research into real solutions for the challenges posed by the customers of Danobatgroup businesses.

A unique ecosystem for innovation

Together with Ideko, we have cultivated a unique ecosystem for innovation. An ecosystem that combines close collaboration with customers, listening carefully to their needs and working side by side with them, and the contribution of value and trust from Ideko's experts.

This collaborative approach involves not only close cooperation with customers, but also addresses challenges with a holistic and visionary approach.

Furthermore, it enables us to stay at the forefront of advanced manufacturing, generating cutting-edge solutions that position us as trendsetters and leaders in the transformation of machine tools and advanced manufacturing.

Open innovation

Danobatgroup has adopted and systematically develops open innovation.

This open innovation mindset in cooperation with external entities and organisations allows us to access diverse knowledge and technologies, accelerating innovation processes and strengthening our competitive position.

Likewise Ideko also gives us access to international benchmark centres.

Our collaborations extend to renowned entities, some of which are mentioned below.

-

BRTA

Basque Research Technology AlianceCollaboration agreement between the Basque Government, the SPRI Group, the Basque Provincial Councils and scientific-technological agents of the Basque Science and Technology Network.

-

CIRP

International Academy for production engineeringThe leading international organisation for applied research in advanced manufacturing.

-

EUSPEN

The European Society for Precision Engineering and NanotechnologyEuropean Community to advance Precision Engineering Science and Technology, Micro-Engineering and Nanotechnology

-

BAIC

Basque Artificial Intelligence CentreCentre that leads and promotes the development of Artificial Intelligence in the Basque Country to improve business competitiveness, among other objectives.

-

AMRC

Advanced manufacturing Research CenterUniversity of Sheffield, a leading centre for research in machining, manufacturing and advanced materials.

-

SCCH

Software Competence Center HagenbergThe Hagenberg Software Competence Centre (SCCH) is an organisation focusing on data science and software with which we collaborate especially in the field of SCT and automation.

-

CFAA

Centro de fabricación avanzado de aeronáuticaA joint centre of the University of the Basque Country to develop advanced manufacturing technologies at levels of development that can be rapidly transferred to the industrial fabric.

-

University of Bremen

University with which we cooperate, especially in the field of grinding technology.

-

BPTD

Basque Precision Technology DistrictAssociation of companies and organisations to support the generation of new industrial activity in the field of precision technologies in the Lower Deba region.

-

University of Waterloo

University with which we cooperate, especially in the field of dynamics and control.

-

ENNE-Fundazioa

Foundation that inspires and generates technological progress in the industrial sector of Gipuzkoa through interaction, collaboration and shared knowledge.